Last Updated on 8 months ago by Lina Wu

PCB fracture is the most common cause of the failure of flexible lights. In addition to external factors such as violent installation and uninstallation, environmental temperature differences caused by thermal expansion and contraction, together with the light structure itself and installation environment, PCBs are subject to repeated pulling and squeezing and fracture occurs.

What’s Thermal Expansion and Contraction?

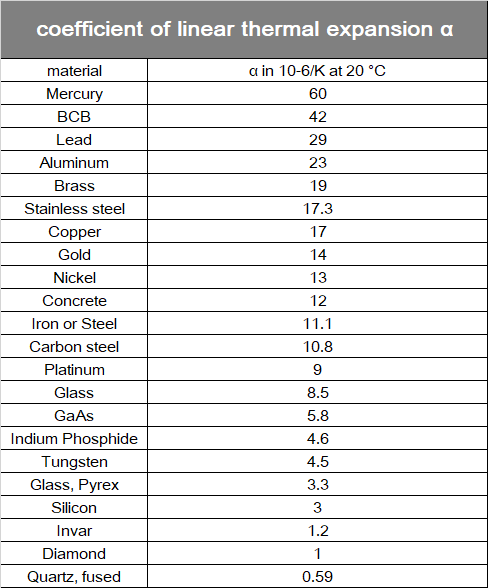

Thermal expansion occurs when you heat a material and it gains more internal energy, and as the atoms within the material move around faster, and the material expands. Thermal contraction occurs when you cool the material down, and the atoms don’t have that much energy. What happens is the material contracts. The coefficient of thermal expansion, often abbreviated CTE, provides a measure of how much a material expands or shrinks when heated or cooled. This is an important consideration for any material or product exposed to extreme temperatures or temperature fluctuations.

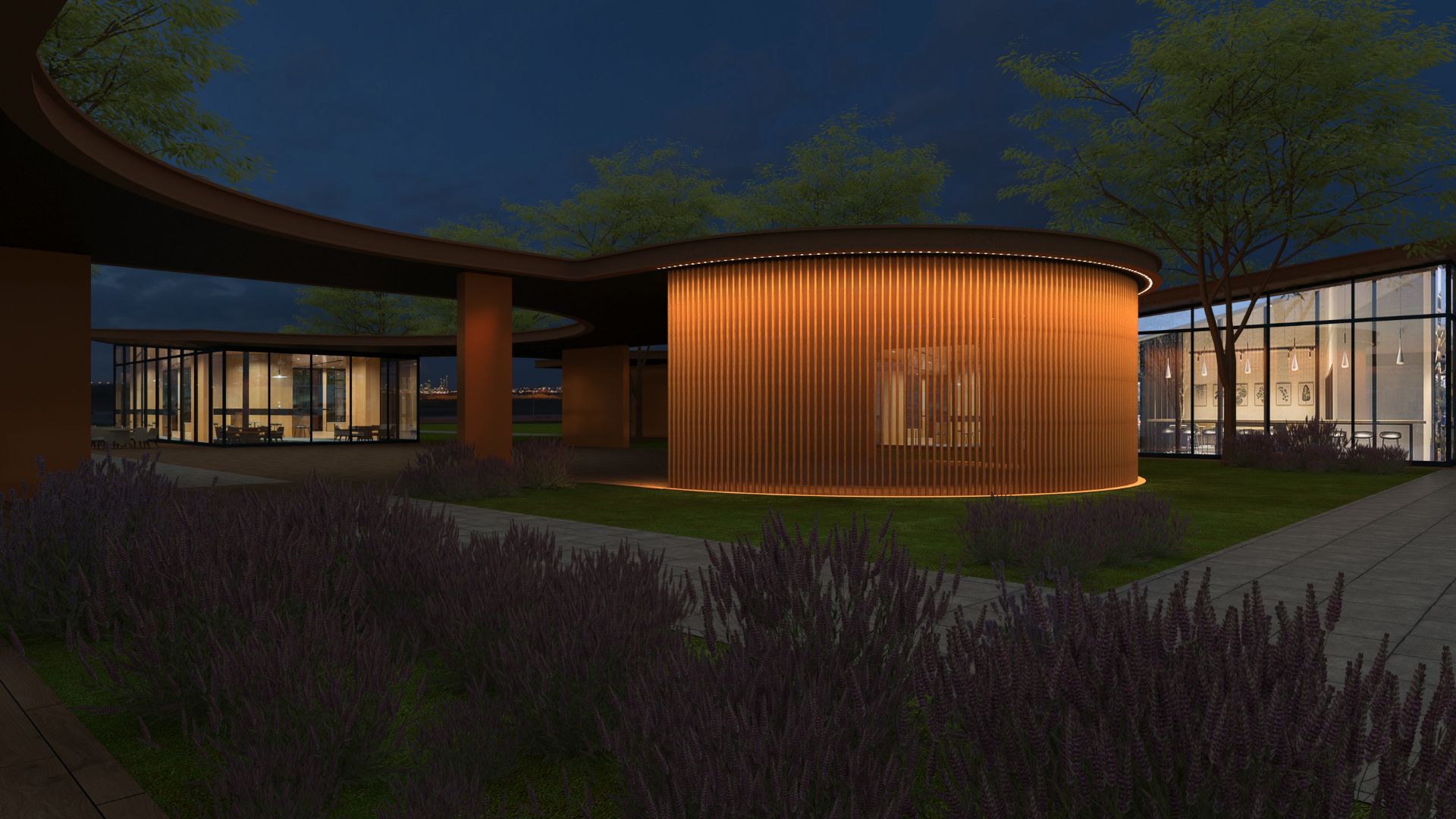

How Thermal Expansion & Contraction Affect Flexible Lights?

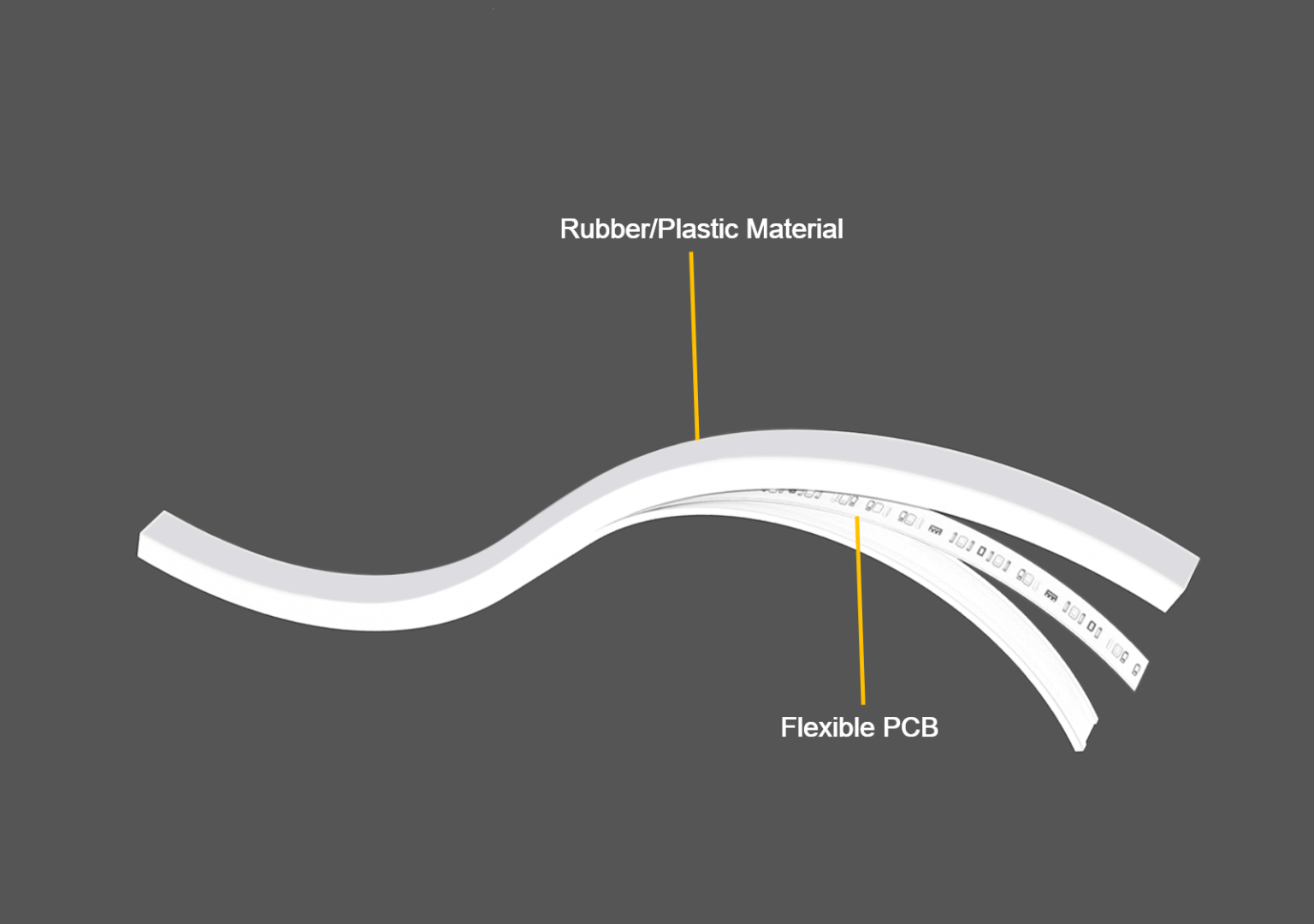

Flexible linear neon light adopts the structure of SMD FPCB and rubber or plastic materials. When a variety of materials are combined and heated or cooled together, due to the thermal expansion coefficient of the materials, these materials will produce internal stress, thus causing pressure on components and thus deformation. When the ambient temperature for the neon flex rises, the expansion produced by the thermal expansion will put the FPCB under strain. When the ambient temperature falls, the cold-induced contraction will work on the FPCB, causing irreversible crease and deformation. Over time, this cyclic thermal expansion and contraction will lead to fatigue-induced fracture caused by repeated stress, eventually damaging the entire FPCB.

CTE for Different Materials

The thermal expansion and contraction happen to almost all solid materials. Each material has a unique coefficient of thermal expansion (CTE). The higher the CTE is, the more it expands when heated.

Data from Wiki Page

| Item | Main Materials |

|---|---|

| Neon Flex Light | Copper (FPCB) + Silicone/PVC |

| Profile | Aluminum/Steel |

CTE: Aluminum > Steel > Silicone > PVC

What are the Constraints on Thermal Expansion & Contraction of Flexible Lights?

Mounting Surface

The mounting surface, whether it is reinforced concrete or wood, will suffer thermal expansion and contraction itself when there is a large temperature swings in the environment over a long period of time. This will have an impact on the installed profiles and lights.

Profiles

What the profile is made of, together with its clamping force, installation length and installation method, plays a role in the contraction of the flexible light.

How to Mitigate Impact from Thermal Expansion & Contraction?

Product Selection

Choose silicone products for environments where large temperature differences is norm because of the smaller CTE coefficient and Twinflex technology.

Pick profiles with better uniformity and clamping force, such as serrated profiles, which could put some restrictions on the expansion and contraction of the light materials.

Installation Precautions

Clear has amassed a great deal of experience over the past 20 years, and is able to solve the failure of neon flex lights caused by PCB fracture in a targeted manner.

Conclusion

How thermal expansion and contraction impacts the light PCB is very complicated and PCB fracture is commonly known as the major cause of light failures. In response, Clear has an exclusive laboratory in place to simulate the thermal expansion and contraction that may occur in real life, hoping to provide professional guidance from product selection to installation and preventlight failures from the very early stage.