Last Updated on 8 months ago by Lina Wu

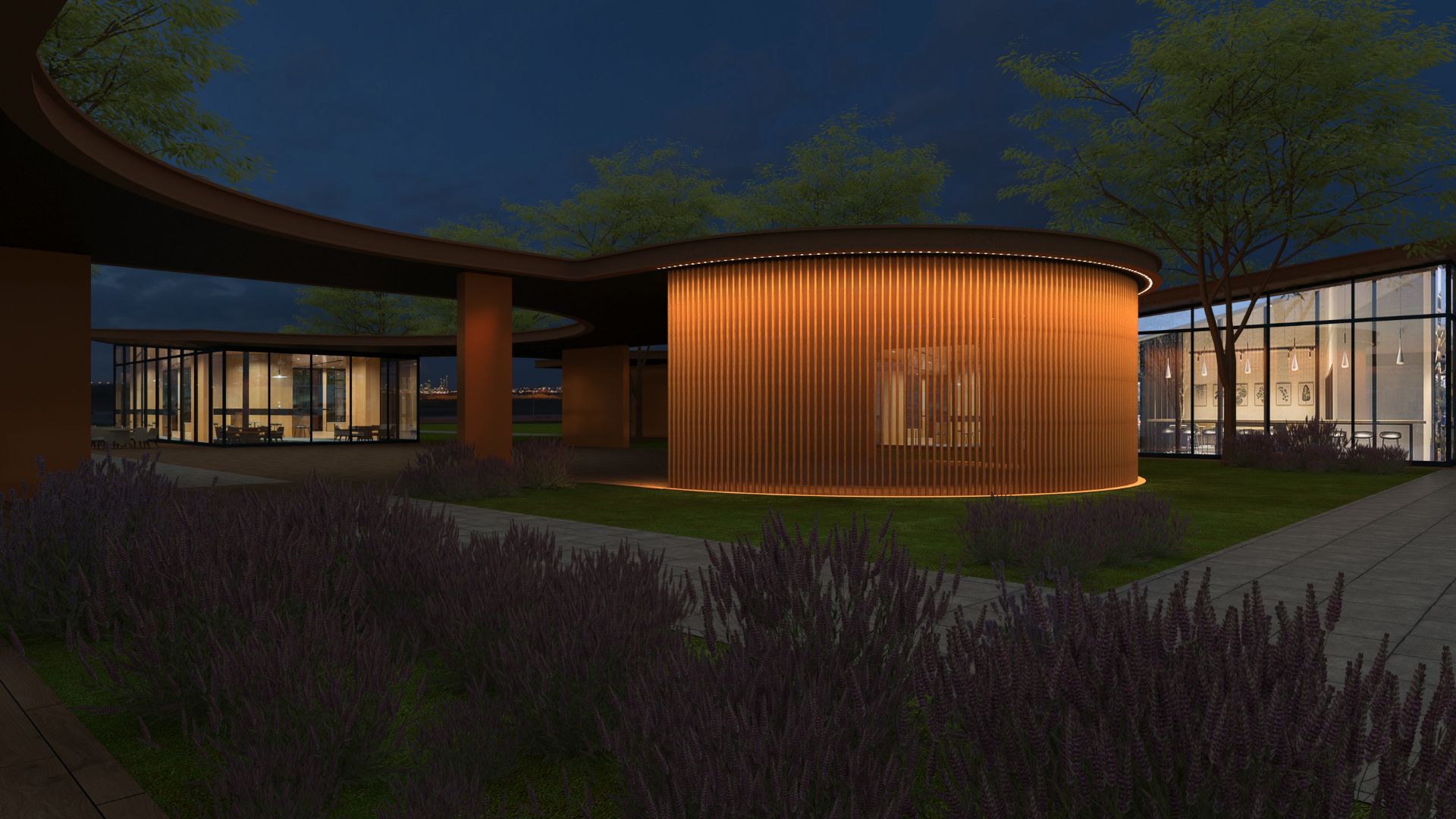

In today’s lighting market, LED neon flex lights are widely used for their flexibility, waterproofing, and high brightness, making them ideal for both indoor and outdoor applications. Powered by SMD (Surface Mount Device) LED technology, these lights deliver energy efficiency and superior brightness. However, their lifespan depends on factors like chip quality, heat dissipation, and environmental conditions. Effective heat management and high-quality materials are essential to prevent performance decline and ensure long-lasting results. This article explores the key factors affecting LED neon flex light lifespan, helping you make informed choices for optimal performance.

LED Chip Quality

- Chip Brand and Process

High-quality LED chips, made with advanced manufacturing and premium materials, significantly extend light lifespan. Well-known brands offer better luminous efficacy, stability, and durability, with slower light decay, ensuring long-term brightness.

- Luminous Efficiency and Heat Dissipation

Efficient LED chips deliver higher light output while reducing energy loss and heat generation. Lower heat keeps the chip and components cooler, slowing aging and extending the light’s overall lifespan.

Elevated Temperature Inside the Luminaire

- Power and Current Relationship

Higher power means higher current, generating more heat. In high ambient temperatures, the luminaire’s ability to dissipate heat is limited, causing internal heat buildup. This accelerates aging of key components like LED chips, leading to faster light decay and a shorter lifespan.

- High Temperature’s Impact on Light Efficiency

High temperatures reduce LED light output efficiency, lowering brightness and affecting performance. Heat can also cause internal materials to expand, creating mechanical stress that compromises structural stability and light efficacy.

- Poor Heat Dissipation Effects

Insufficient heat dissipation design prevents timely heat release, worsening component aging. High temperatures speed up the degradation of LED chips and phosphors, reducing light efficiency and ultimately shortening the luminaire’s lifespan.

Effect of Dust on Brightness

Dust covering the luminaire’s luminous surface blocks part of the light output, reducing brightness. Over time, dust buildup worsens, leading to a more noticeable decline in brightness.

Dust not only dims the light but also accumulates on the luminaire’s surface or radiator, hindering heat dissipation. This raises the internal temperature, accelerating the aging of the LED chip and phosphor, and further reducing luminous efficacy.

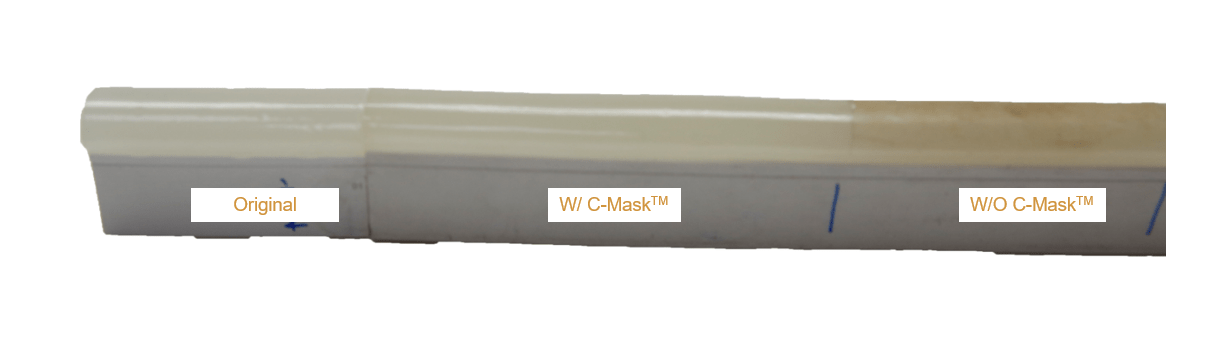

In 2015, we introduced our proprietary C-Mask™ technology, a protective treatment designed to self-clean and shield the light surface from harsh weather conditions like sun exposure and dust. This innovative solution helps maintain vivid light color brilliance, ensuring long-term performance and durability for outdoor use.

Testing Condition: Outdoor testing for 120 days

Thermal Management

- Thermal Structure

The design of the thermal structure plays a vital role in managing heat for luminaires, particularly high-power and LED lights. A well-optimized thermal structure helps lower internal temperatures, extends lifespan, and minimizes light decay.

With the same materials like cylindrical housings or circuit designs, hollow structures in LED strips often provide better heat dissipation than solid ones. This is because the hollow space allows for improved air circulation, which helps disperse heat more effectively. However, hollow designs typically have weaker waterproofing and mechanical strength compared to solid structures—unless they are specially treated (e.g., sealed coatings or reinforced frameworks).

- LED Density

Higher density means greater thermal load. LED density (LEDs/meter) directly affects heat generation per unit area. For example: A 120 LEDs/m strip produces nearly 2× the heat of a 60 LEDs/m strip. Without adequate heat dissipation, high-density strips risk localized overheating, leading to accelerated light decay or reduced lifespan.

Heat distribution is challenged by LED spacing. With high-density lights, tight LED spacing causes heat superposition, making it harder to dissipate heat. For low-density strips, sparsely-spaced LEDs allow more uniform heat distribution, reducing thermal stress.

- Heat Dissipation Material

High-power luminaires demand robust heat dissipation capabilities. Poor heat management can cause heat buildup, speeding up the aging of components. High-quality materials, such as the high-performance silicone used in CLEAR, provide excellent thermal conductivity, ensuring efficient heat transfer. Silicone’s flexibility and softness allow it to fit snugly around heating elements, boosting heat dissipation efficiency.

- Heat Dissipation Surface Area

Increasing the surface area of the heat dissipation structure enhances its efficiency. By expanding the heat sink’s surface area or incorporating advanced designs, thermal performance improves significantly, effectively reducing the luminaire’s internal temperature.

- PCB Property

The width and thickness of the PCB directly impact its current-carrying capacity and thermal performance. Thinner PCBs tend to have poorer heat dissipation due to reduced material mass and conductivity.

TwinFlex™ technology combines FPCB (Flexible Printed Circuit Board) with a copper belt, significantly enhancing mechanical strength, heat dissipation, and current-carrying capacity while minimizing voltage drop.

- Other Factors

The installation environment and heat dissipation materials indirectly affect LED strip lifespan. Proper ventilation facilitates convective cooling and prevents heat buildup. Aluminum profiles (with higher thermal conductivity) provide significantly better heat dissipation than plastic alternatives.

Want your LED lights to last longer? It comes down to a few key things: the quality of the LED chips, keeping the internal temperature in check, preventing dust buildup on the light surface, and using smart heat dissipation designs. To get the most out of your luminaires, pick top-notch LED chips, focus on good thermal management, clean them regularly, and go for cutting-edge heat dissipation tech. These easy steps will keep your lights shining bright and working well for years!